Industrial chiller refrigeration heat exchanger introduction and analysis of heat transfer process

August 30, 2023

Industrial chiller refrigeration heat exchanger introduction and analysis of heat transfer process: We often say that the industrial chiller cooling heat exchanger, mainly refers to the condenser and evaporator, they are the two major parts of the refrigeration four major, direct Affects the ability and efficiency of the system to absorb and release heat. Condenser and evaporator all involve phase change heat transfer, which is a major feature of these two types of refrigeration heat exchangers. In addition, some refrigeration systems have intercoolers, supercoolers, etc., and their principles are similar to those of ordinary heat exchangers.

For cooling water towers used in water-cooled chillers, it is an indispensable water-cooling device for large-scale centralized cooling systems. Although it cannot be considered as a refrigerating heat exchanger, it does participate in heat exchange, and we have included it in this category.

So, what is the heat transfer process? In an industrial chiller refrigeration system, the high-temperature, high-pressure refrigerant vapors entering the condenser are condensed into liquid by air or cooling water in the ambient environment; the low-temperature refrigerant liquid entering the evaporator comes from the surrounding air or the brine. Endothermic and gasified, so that a certain area of the temperature drop, to achieve the purpose of refrigeration. The process of transferring heat between the refrigerant and the surrounding fluid through the pipe wall becomes a heat transfer process.

According to the form of the solid wall, there are mainly three kinds of heat transfer processes in the commonly used refrigeration equipment, namely the heat transfer process through the flat wall, the heat transfer process through the round tube, and the heat transfer process through the Le wall.

1, flat wall heat transfer: When the heat transfer wall for a flat, or can be approximated as a flat wall, heat from one side of the high temperature liquid through the wall surface to the other side of the cryogenic fluid, formed a flat wall Heat transfer.

2. Circular tube heat transfer: In the condenser and evaporator of a refrigeration system, copper and steel heat transfer tubes are widely used, so heat transfer through the tube is very common.

3. Heat transfer from Le wall: It can be seen from the heat transfer equation that the heat transfer amount per unit time increases not only with the increase of the heat transfer coefficient, but also with the increase of the heat transfer surface. When the heat transfer coefficient is increased to a certain degree and it is difficult to increase it, the heat transfer amount can be increased by increasing the heat transfer denomination, and it is usually processed on the heat exchange wall by processing a lew or fin.

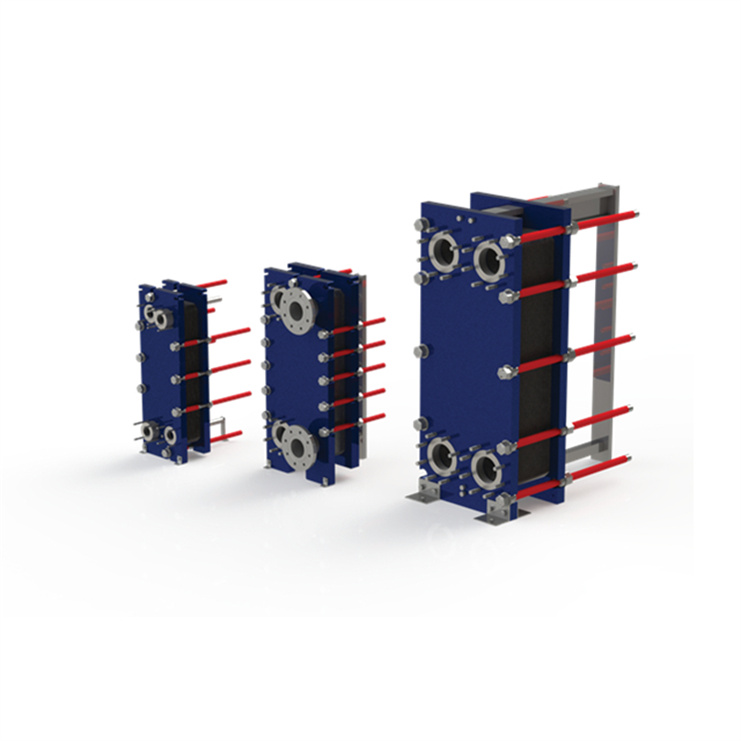

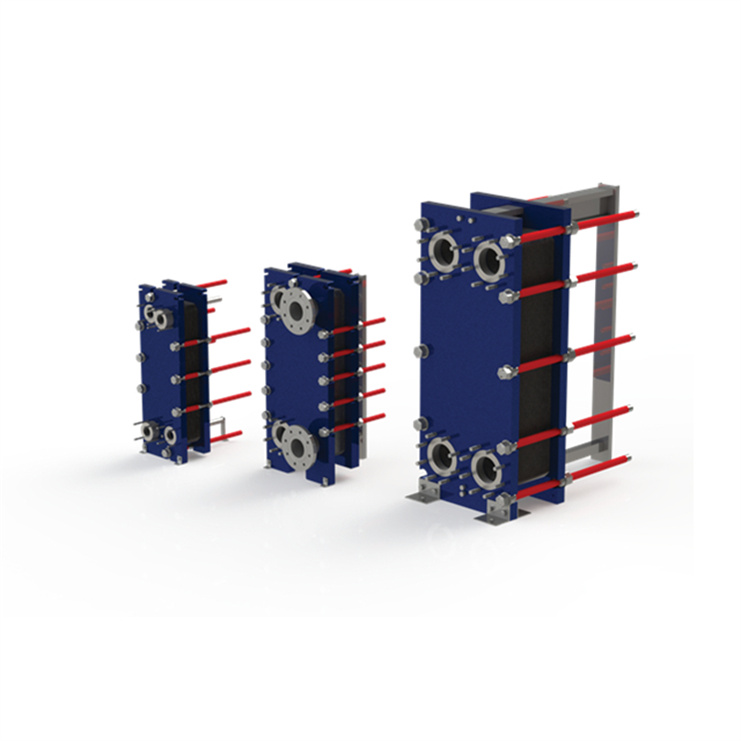

Brazed plate heat exchanger can be used in the power industry: high voltage transformer oil cooling, generator bearing oil cooling, etc.