Discuss the principle and several characteristics of plate heat exchanger

August 09, 2023

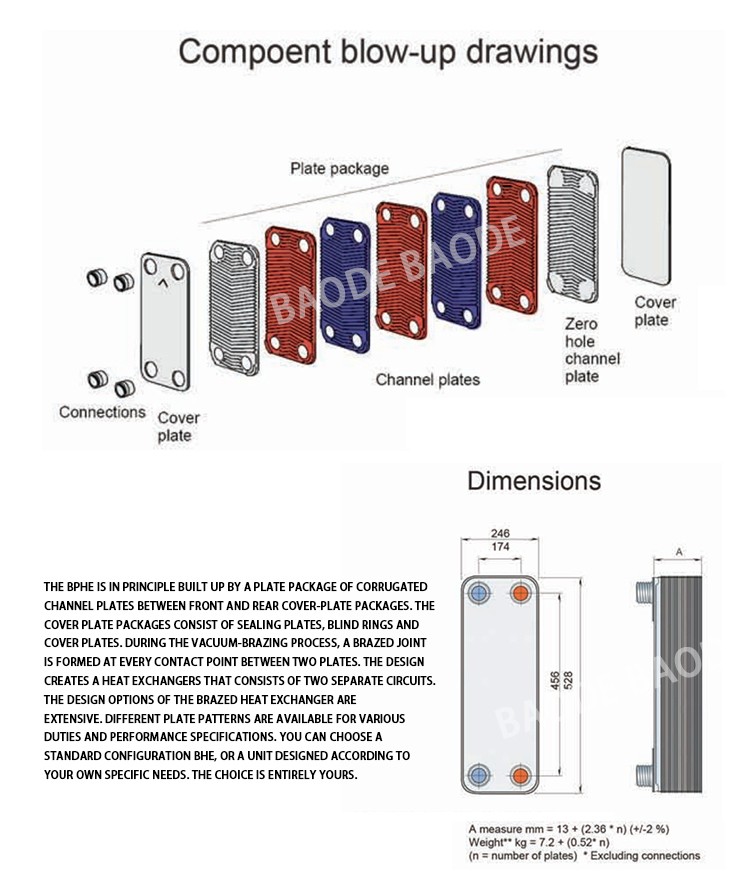

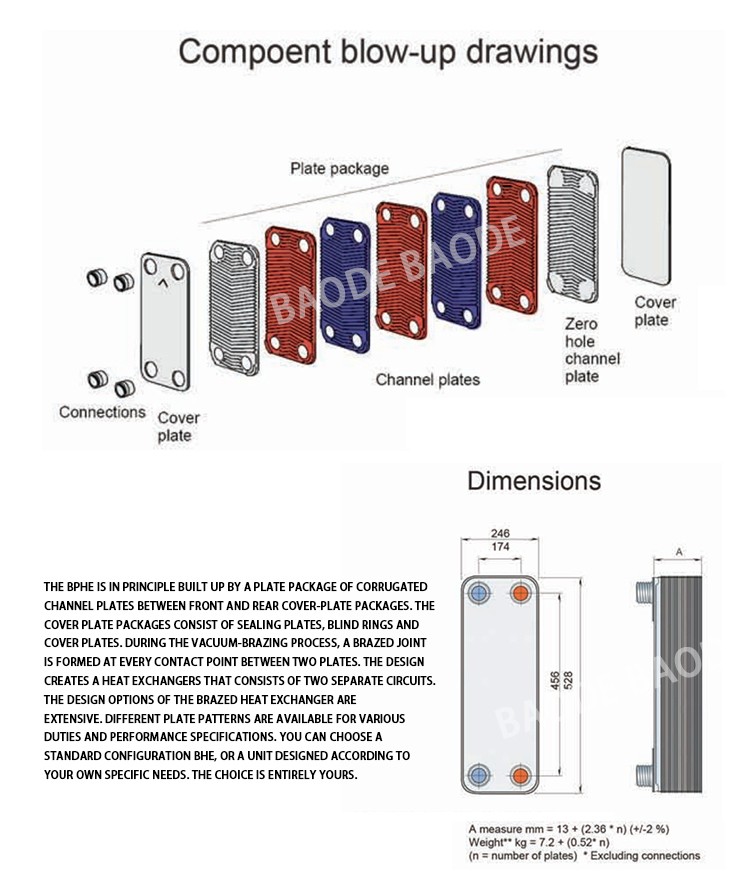

Plate heat exchangers use metal plates for heat exchangers and have very high heat transfer efficiencies, which are larger than those exposed by conventional heat exchangers. This facilitates heat transfer and greatly increases the rate of temperature change. Plate heat exchangers are now common heat exchangers. And very small brazed versions are used in millions of combined boiler hot water sections. High heat is such a small physical size conversion efficiency, which increases the combination of domestic hot water (domestic hot water) boiler flow. Small plate heat exchangers have had a large impact on domestic heating and hot water. Plate liners are used between larger commercial versions, and smaller versions are often brazed.

The concept behind the heat exchanger is to contain a pipe or other vessel that uses heating or cooling to transfer it to one of the other fluid hot fluids. In most cases, the heat exchanger consists of a coil containing a fluid passing through a conduit containing another liquid chamber. The walls of the pipe are usually metal or other materials with high thermal conductivity to facilitate, while the larger meeting room enclosure meets, is made of a plastic or has a thermal insulation coating to prevent heat escape from the heat.

The inventor of the plate heat exchanger (plate heat exchanger) Dr. Seligman Richard in 1923 and revolutionary indirect heating methods and liquid cooling. Dr. Seligman Richard was founded in 1910 by the Aluminum Factory and Container Co., Ltd. is a professional manufacturing company providing welding vessels for the winery and vegetable oil industry companies.

Plate heat exchangers have the following characteristics:

Compact structure: the space occupied by the plate heat exchanger is the smaller one of the various heat exchangers. Under the same heat transfer conditions, the plate heat exchanger covers only 1/3 of the shell-and-tube heat exchanger. ~1/4, and no additional maintenance space is required for disassembly.

High heat transfer coefficient: Since the medium flowing in the plate group can form turbulent flow at a low Reynolds number (Re), and the smooth plate is not easy to generate dirt, it has very high heat transfer efficiency in general water. In the heat exchange with water, the heat transfer coefficient of the plate heat exchanger can reach 6000w/m2 °C or more, which is 3-8 times higher than that of the shell-and-tube heat exchanger.

High heat recovery rate: due to high heat transfer coefficient, excellent flow ratio characteristics and complete reverse flow, the heat transfer temperature difference can be selected very low, so it is very suitable for low-level heat recovery, using a single plate heat exchanger to achieve 90% The above heat recovery rate is economically feasible.

Adaptability: Foldable plate heat exchangers have unmatched adaptability. After installation, the sheet metal group can increase or decrease the process requirements for expansion and contraction. Low stagnation flow: Due to its small flow path and small stagnation flow, it can be started quickly, the reaction is changed quickly when the control operation is changed, and the weight of the equipment is greatly reduced.

Convenient maintenance: the design of the plate makes it free of dead zones, so it can be chemically cleaned on site without disassembly. The detachable plate heat exchanger can also be easily opened for thorough mechanical cleaning.

In order to improve the use of plate heat exchanger temperature and pressure, expand its scope of use, domestic and foreign have developed and manufactured a variety of welded plate heat exchanger, the welded plate heat exchanger are divided into full-welded and semi-welded two categories. Welded plate heat exchangers have been more and more used in chemical, petroleum, power, metallurgy and other fields of heating and cooling, cold, evaporation and heat recovery process. Gasket plate heat exchanger for condenser is very popular in the market.